In this ever-changing job market and complicated supply chain, warehouses may need help from third-party organizations to keep up. To ensure their inventory is always in check, companies must now invest in inventory control solutions that will help streamline product flow and optimize operations.

Corporate leaders now rely on specialized software for inventory management solutions to manage and affordably deliver their products to buyers. This cutting-edge technology provides a reliable, streamlined process that guarantees customers receive their orders with minimal delays.

Warehouse Management Solution (WMS) consists of hardware and software frameworks including RFID technology to help managers keep track of products within the warehouse.

The inventory management system may be the first thing that comes to mind when considering RFID technology. It is designed to eliminate human errors, enhance productivity, and ensure a smooth stock flow. Technology allows logistic companies to keep everything orderly and running at its fullest potential.

Commonly known as RFID (Radio frequency identification) sensor systems are one of the most transformative and potent technologies used in modern warehouses and logistics centers. This guide will explain how RFID use in warehouse management systems significantly improves efficiency, accuracy, and safety.

Defining RFID

RFID stands for Radio Frequency Identification and is a technology consisting of RFID tags, readers, antennas, and software applications. It uses radio frequencies to identify items in the warehouse by their unique identifier. The tag can be attached to products or inventory containers, such as pallets and boxes.

Thanks to RFID technology, it's now possible for anyone to tackle inventory tracking and identification with ease. Choosing the right warehouse management system gives warehouse managers the power to effortlessly keep tabs on where their goods are at all times within the supply chain - ensuring that every item is in its right place.

Booming demand of RFID and Implementation in Logistics

Deciding to commit to RFID technology promises an array of advantages for warehouses, mainly improved inventory accuracy up to a staggering 99.99%.

By investing in RFID, warehouse managers can witness firsthand the grandeur of a highly reliable supply chain system. Introducing RFID technology into their supply chain has enabled manufacturers and distributors to achieve a remarkable 80% increase in shipping/picking accuracy.

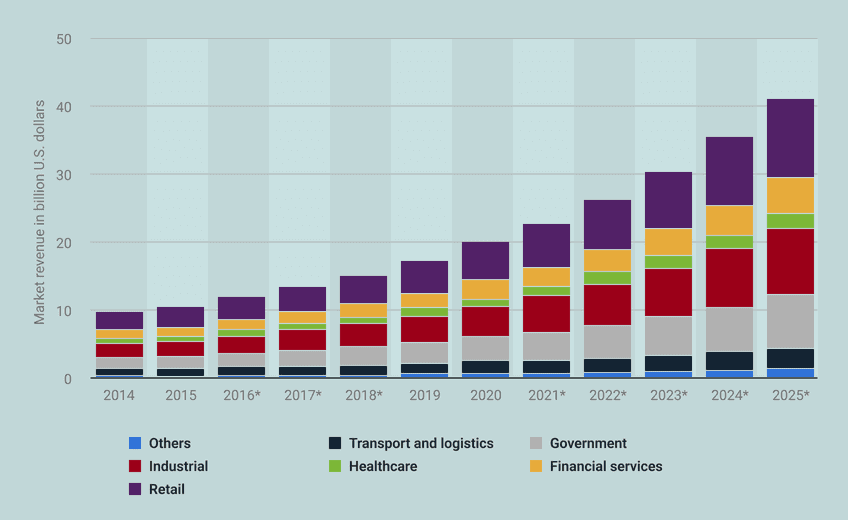

Moreover, data from Statista reveals that the retail sector of the RFID market yielded an astonishing 3.8 billion U.S. dollars back in 2017 - demonstrating just how powerful this transformative technology can be when utilized correctly.

The RFID market is booming, having topped $10.41 billion in 2020 and is expected to increase even further to reach an incredible $25.47 billion by 2030 - a CAGR of 9.6% from 2021-2030!

By incorporating RFID technology into their supply chain, companies can witness a remarkable 90% reduction in receiving time. This technology further increases inventory visibility and availability from 2% to 20%, giving warehouses and distribution centers an immense advantage over those who don't utilize it.

Implementing RFID technology typically boosts inventory count accuracy from a meager 63% to an astonishing 95%. RFID tagging on merchandise allows manufacturers to boost their inventory count rates from a mere 200 to an astonishing 12,000+ items per hour.

These numbers show how to improve warehouse efficiency with RFID technology is a game-changer for businesses that value accuracy, speed, and efficiency.

How does RFID work?

An RFID system comprises three essential components - a scanning antenna, a transceiver, and a transponder. The combination of the two former elements makes for an RFID reader or interrogator.

With this powerful mechanism at your disposal, you can gain unprecedented control over assets as well as maximize the efficiency and accuracy of operations.

RFID technologies are composed of readers and tags. Fixed readers remain in one place, while mobile readers can be relocated easily. When the tag is activated by radio waves from a reader's antenna, it sends back its information which is translated into data for further use.

This simple yet effective process allows businesses to have more accurate tracking capabilities with ease!

Incorporated in the RFID tag, a transponder dictates its read range that can vary due to distinct elements such as the type of tag and reader employed, frequency level, and the presence of disturbances from other tags or readers in the vicinity. Enhanced energy sources maximize these ranges even further.

How does RFID work in a warehouse?

Warehouse Management Software (WMS) integrated with RFID technology makes it easy to track orders and inventory moving through a warehouse. This combination helps ensure that goods are in the right place at the right time while providing real-time data on stock levels and order statuses.

An RFID tracking system is a must-have for warehouses, making inventory management simpler and more streamlined. This typically involves several stages in which each step leads to better control of the goods:

- Goods are received, scanned, and registered in the warehouse management software

- RFID tags are placed on or inside the products

- Products pass through a scanning tunnel that reads the RFID tags

- The tags' data is then translated into data for further use and tracked in real-time

- A report is generated and can be used to track the inventory's progress

- Stock levels are recorded to ensure the accuracy of orders

With an RFID warehouse tracking system, items can be scanned and cataloged from anywhere, even hidden behind boxes or pallets. Inventory Management Software integrated with RFID helps ensure that goods are received in good condition and on time.

Read more: Explore the advantages of RFID for warehouse management

Barcode Limitations in Warehouse management

Barcode Limitations in WMS are widely known and documented. They are prone to wear and tear, require scanning from a short range and need physical interaction for scanning, which is not always possible when the items are in bulk.

Utilizing bar code technology can reap numerous rewards; however, a few problems must be considered before making an informed decision. A few of these important matters include:

Limited range

Barcode scanners can only read labels in close proximity, which means a lot of manual labor is necessary if you have large amounts of items to process.

Less accurate readings

It’s easy for bar codes to become scratched or damaged, making them difficult to read correctly. This leads to inaccurate data, which can be costly for any business.

Time-consuming

Scanning each bar code one by one could be more efficient, especially as the number of items increases. This could lead to delays in order processing and customer service considerably affected.

Costly

If your business consists of only a few products and minimal orders, the cost to utilize technology may be excessive. Before taking any action, calculate a return on investment to ensure its worthiness.

Warehouse Management System Is Required - Before you can introduce barcodes into your operations, a warehouse management system must be in place. Additionally, personnel will need to be hired or reassigned to handle the installation and maintenance of these items.

Read more: Choose the best technology for your warehouse - RFID or Warehouse

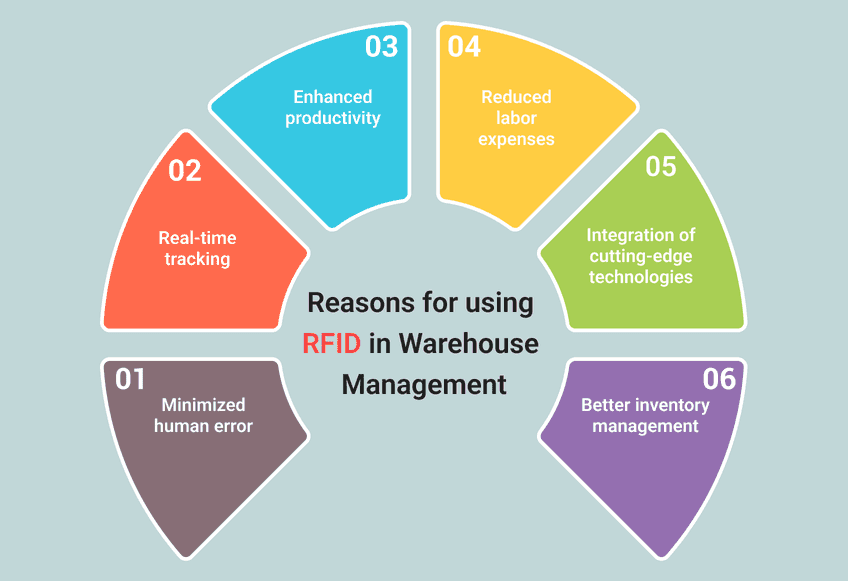

Reasons for using RFID in Warehouse Management

RFID technology offers many advantages over more traditional barcode scanning. With the ability to read data from a longer range, RFID in the Warehouse is much faster and more accurate than barcodes, which makes it an ideal solution for managing large warehouses. Here are some reasons for using RFID in the warehouse:

Minimized human error

RFID helps reduce human error by eliminating the need to input data manually.

Real-time tracking

RFID tags can be used for real-time tracking of products and inventory, allowing managers to keep track of their goods efficiently. RFID-based warehouse management software can also be used to monitor workers' performance in relation to their tasks.

Enhanced productivity

With RFID, fewer people are needed for inventory management tasks as the process is automated. This helps to reduce overhead costs and increase productivity.

Reduced labor expenses

By having an automated system in place, there is less need for manual input from employees, which results in reduced labor costs.

Integration of cutting-edge technologies

By using RFID, you can easily and quickly integrate cutting-edge technologies such as the Internet of Things (IoT), artificial intelligence (AI) and blockchain into your warehouse management system. This helps to streamline operations and increase efficiency.

Better inventory management

Using RFID in warehouse management helps ensure that the right product is delivered at the right time and place. RFID tags can be attached to products, allowing for easier and more accurate tracking, even when hidden behind boxes or pallets.

Inventory Management Software integrated with RFID helps to make sure that goods are received in good condition and on time.

Read more: Discover how to improve warehouse management solutions with RFID

Workflow automation

With RFID, manual, labor-intensive tasks such as order picking and inventory management can be automated. This reduces waiting time and improves the efficiency of operations.

Simplified parts are tracking

RFID tags can make tracking and managing parts, components and supplies easier. Using RFID in the Warehouse, you can keep track of parts even when they are stored in different locations or shipped off site. This helps reduce the cost of missing or incorrect orders and improve customer service.

Closing thoughts

Using RFID in the Warehouse is an efficient, cost-effective way to manage inventory and streamline operations. By automating tasks such as order picking and inventory management, you can save money on labor costs while also maximizing productivity.

Additionally, by integrating cutting-edge technologies into your warehouse management system, you can ensure that your goods are tracked accurately and shipped on time.

RFID in the warehouse can help your company remain competitive and profitable with the right strategy.

It’s important to research and understand how RFID will fit into your warehouse systems. In some cases, if there are too many technical constraints or budgetary restrictions, RFID might not be the right solution.

However, if you take the time to understand how RFID can benefit your business and make an informed decision, it can be a great addition to your warehouse.

Finally, after implementing RFID in the warehouse, proper personnel must be hired or reassigned to handle the system's installation and maintenance to ensure it’s running optimally. Once this is done, you can enjoy the benefits of improved warehouse operation with RFID and increased efficiency.